NEC, Birmingham

Booth N80

The W Exhibition has officially relaunched as the Materials & Finishes Show. "Materials & Finishes Show is the UK's primary platform for carpenters, joiners, machinists and installers to see running woodwork machinery, the latest materials, components, software, tools and innovations for the woodworking sector." Compass Software will be exhibiting as usual. We are looking forward to seeing you there!

Compass Software will be exhibiting from 21.05.2024 -24.05.2024 at the Italian trade fair Xylexpo in Fieramilano at the SCM booth in Hall 3.

You can also find more information about the trade fair and the offer at SCM here.

We look forward to seeing you!

Georgia World Congress Center

Building B · Booth B4338

Compass Software once again will exhibit at the IWF in Atlanta. The IWF is the largest showcase of machinery, materials, supplies and services in North America for woodworking and related industries. We are looking forward to showing you our newest features in Atlanta!

Kongresszentrum Innsbruck

Compass Software will be exhibiting at the Forum Woodwork in Innsbruck as every year. The topic of the forum is once again "Practical experience – Practical application". We are looking forward to seeing you there!

![[Translate to Amerikanisch:] BuildTec Group](/fileadmin/_processed_/d/8/csm_buildtec-software-group.q_8948d55fd5.jpg)

![[Translate to Amerikanisch:] Compass Software Weihnachtsfeier](/fileadmin/_processed_/b/8/csm_Compass-Software-Weihnachtsfeier_q_951c3d820b.jpg)

![[Translate to Amerikanisch:] Ticketsystem Compass Software](/fileadmin/_processed_/4/7/csm_Ticketsystem_q_2de73afeda.jpg)

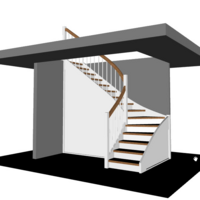

![[Translate to Amerikanisch:]](/fileadmin/_processed_/4/2/csm_T-Optik-Treppe-2_d9f55aa8e0.jpg)

![[Translate to Amerikanisch:] Compass Software stellte abermals auf dem 16. Europäischen Kongress beim FORUM-HOLZBAU in Köln aus. Das Thema: "Effizientes bauen mit Holz im urbanen Raum".](/fileadmin/_processed_/6/9/csm_MicrosoftTeams-image__12__01_4084268f96.png)

![Klaus Eilers [Translate to Amerikanisch:] Klaus Eilers](/fileadmin/_processed_/b/4/csm_Compass-Software-Klaus_5a5f9b4051.jpg)

![[Translate to Amerikanisch:] Automatische XML Schnittstelle Compass Software](/fileadmin/_processed_/9/7/csm_Compass-Software-XML-Station_5c29ce8f12.png)

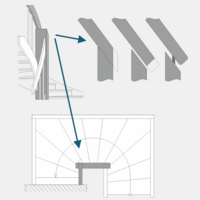

![[Translate to Amerikanisch:] Bearbeitung der Stirnseiten von Krümmern mit Compass Software.](/fileadmin/_processed_/3/4/csm_Kruemmer-Stirnseite-Schlichten_q_a755506ac8.jpg)

![[Translate to Amerikanisch:] Wussten Sie schon, dass wir Schulungen auch in unserem Büro in Bad Endorf (Landkreis Rosenheim) anbieten?](/fileadmin/_processed_/a/0/csm_Compass-Software-Niederlassung-Sued-Bad-Endorf-2_333575db90.jpg)

![Ludger Ostendarp [Translate to Amerikanisch:] Ludger Ostendarp](/fileadmin/_processed_/8/e/csm_Ludger_Ostendarp_8aaf08373a.jpg)

![[Translate to Amerikanisch:] Treppe des Jahres 2022 Treppen.de](/fileadmin/_processed_/2/e/csm_Treppe-des-Jahres-2022-Badge-Architektur-51380dfb_0ff297fa57.png)

![[Translate to Amerikanisch:] Detlef Hollinderbaeumer](/fileadmin/_processed_/6/7/csm_Detlef-Hollinderbaeumer_ff649ae9df.jpg)

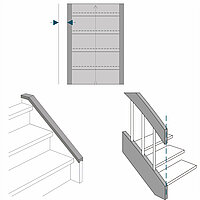

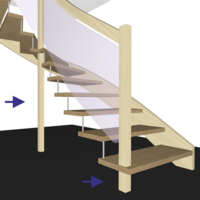

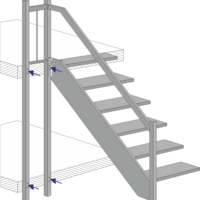

![[Translate to Amerikanisch:] Externe Treppen können in Compass Software leicht eingelesen werden.](/fileadmin/_processed_/2/9/csm_Externe-Treppe_b388525644.jpg)

![[Translate to Amerikanisch:] Candy Bolten](/fileadmin/_processed_/6/d/csm_Compass-Software-Candy_38af13ec06.jpg)

![[Translate to Amerikanisch:] Compass Software Digital Jetzt Förderung](/fileadmin/_processed_/8/b/csm_Compass-Software-Digital-Jetzt-Foerderung_6c0d7e14f8.jpg)

![[Translate to Amerikanisch:] Compass Software als Titelthema in der HOB](/fileadmin/_processed_/c/9/csm_HOB_Compass_Software_GmbH_Titelseite-u-Story_cb68e8d489.jpg)

![[Translate to Amerikanisch:] Compass Software Artikel in Mikado 04/2020](/fileadmin/_processed_/e/9/csm_Compass_Software_Mikado_04-2020_2a52427d2e.jpg)

![[Translate to Amerikanisch:] Artikel in der BM über Compass Software Treppen im bunten Materialmix.](/fileadmin/_processed_/7/4/csm_BM_04_2020_Treppen_im_bunten_Materialmix_65bce4bb30.jpg)

![Robin Valerius [Translate to Amerikanisch:] Robin Valerius](/fileadmin/_processed_/0/a/csm_Compass-Software-Robin_1dd5e7d0ce.jpg)

![[Translate to Amerikanisch:] Compass Software Geschäftsführer Detlef Hollinderbäumer mit dem Entwicklerteam](/fileadmin/_processed_/0/1/csm_IMG_5630_b_8ce550b177.jpg)

![[Translate to Amerikanisch:] In der BSP Spezialausgabe des Holzkuriers zum aktuellen viel gefragtem Thema Brettsperrholz wird die Vollautomatische Produktionssteuerung und -kontrolle bei der Firma HASSLACHER NORICA TIMBER vorgestellt.](/fileadmin/_processed_/c/8/csm_20190820_120206_f55449eda0.jpg)

![[Translate to Amerikanisch:] Wir haben Zuwachs bekommen: Christian Rotte unterstützt seit August dieses Jahres das Compass Software Entwicklerteam.](/fileadmin/_processed_/3/3/csm_Compass-Software-Christian-Rotte_2ba7d3adde.jpg)

![[Translate to Amerikanisch:] Compass Software Service Leiter Gereon Max hat am 03.10.2019 beim Sparkassen Phoenix-Halbmarathon in Dortmund teilgenommen.](/fileadmin/_processed_/2/b/csm_Compass_Software_Gereon_Max_Starter_LC_Rapid_dafde657ca.jpeg)

![[Translate to Amerikanisch:] Die Firma Treppenbau Voß GmbH & Co. KG setzt seit Dezember 2018 das Plattenoptimierungsmodul 2.0 von Compass Software ein.](/fileadmin/_processed_/0/e/csm_Compass-Software-Voss-3_7869ab177e.jpg)

![[Translate to Amerikanisch:] Geschäftsführer Dirk Elsner der Firma Luxholm Bauelemente Werk GmbH, berichtet von Compass Software.](/fileadmin/_processed_/4/5/csm_Compass-Software-Luxhom_2f610196e7.jpg)

![[Translate to Amerikanisch:] Die Fertigung der Teile im Wechsel ist mit dem Compass Software BTL-Prozessor mühelos möglich.](/fileadmin/_processed_/4/c/csm_Elemente_002_6cb56f10cc.jpg)

![[Translate to Amerikanisch:] Compass Software Nutzer Droomtrappen aus den Niederlanden baute kürzlich einen eigenen Pfostenspanner für die Produktion.](/fileadmin/_processed_/7/1/csm_Compass-Software-Doomtrappen-Pfostenspanner2_73616ca1ba.jpg)

![[Translate to Amerikanisch:] Trappen Verschaeve setzt Roboter zur Produktivitätssteigerung ein](/fileadmin/_processed_/8/8/csm_DSC_0981_9df562e511.jpg)

![[Translate to Amerikanisch:] Drei Studenten der Fachschule Holztechnik in Melle haben für ihre Technikerarbeit im Fachbereich Fertigungstechnik eine eindrucksvolle Holztreppe selbstständig fertiggestellt.](/fileadmin/_processed_/6/f/csm_IMAG1213_d72d20d9d1.jpg)

![[Translate to Amerikanisch:] Ein Compass Software Techniker besuchte Dinkelhausbetriebe im Januar um die Mitarbeiter zu schulen und die 5-Achs HOMAG Venture L anzuschließen.](/fileadmin/_processed_/8/f/csm_20190320_112740_7bef60e109.jpg)

![[Translate to Amerikanisch:] Compass Software Techniker Alexander Hübner hat seine erste eigenständige Installation bei der Firma S u. W Wohn-Holz GmbH aus Sachsen erfolgreich abgeschlossen.](/fileadmin/_processed_/9/d/csm_Compass-Software-SuW_d537cf95a4.jpg)

![[Translate to Amerikanisch:] 2018 nahm der Compass Software Techniker die neue SCM Accord 25 fx bei Trappentoko in Betrieb](/fileadmin/_processed_/a/6/csm_Compass-Software-Trappentoko_fa5c1f9bfc.jpg)

![[Translate to Amerikanisch:] Compass Software hat Anfang November den Fensterbauexperten Dittmar Siebert zu einer umfangreichen Weiterbildung unseres Teams nach Dortmund eingeladen.](/fileadmin/_processed_/9/b/csm_Fensterbau-Workshop-1_6b7f3d5ed2.jpg)

![[Translate to Amerikanisch:] Compass Software Techniker Steven hat im September an der Werkstattbesichtigung unseres Kunden Loudoun Stairs aus Purcellville, VA teilgenommen.](/fileadmin/_processed_/c/4/csm_SMA-2018-LoudounStairs_b90ffc8ff1.jpg)

![[Translate to Amerikanisch:] Azubi Robin Valerius aus dem Compass Software Entwicklerteam.](/fileadmin/_processed_/1/1/csm_Compass-Software-Robin_0a049ffa2a.jpg)

![[Translate to Amerikanisch:] Unser Service Team wird seit Anfang August von unserem neuen Azubi Sebastian Bäcker verstärkt.](/fileadmin/_processed_/2/7/csm_Compass-Software-Sebastian_c63eee1e9a.jpg)

![[Translate to Amerikanisch:] Die IWF 2018 in Atlanta, GA war ein voller Erfolg. Unsere Kollegen aus dem Büro Atlanta vertraten Compass Software auf der Branchenmesse.](/fileadmin/_processed_/e/e/csm_Compass-Software-IWF-2018_4565ea4ef4.jpg)

![[Translate to Amerikanisch:] Wir haben zum Ende Juli 2018 langjährige Compass Software Entwicklerin Brigitte Streicher in den Ruhestand verabschiedet.](/fileadmin/_processed_/f/f/csm_Brigitte-Compass-Software_fcc4b8f01e.jpg)

![[Translate to Amerikanisch:] Ein Compass Software Service Techniker hat Ende Juli bei unserem langjährigen Kunden Tischlerei Kleeberg eine neue Maka PE 90 5-Achs-Maschine installiert.](/fileadmin/_processed_/0/d/csm_Compass-Software-Kleeberg_79be3ae82f.jpg)

![[Translate to Amerikanisch:] Seit Montag verstärkt Abdullah Orabi - unser neuer Auszubildender - das Compass Entwicklungsteam.](/fileadmin/_processed_/7/0/csm_Compass-Software-Abdullah_e6b75a3773.jpg)

![[Translate to Amerikanisch:] Das Service Team hat Anfang Juni im Rahmen eines größeren Projekts bei der Firma Köhler aus Sachsen die Compass Software Treppenbaulösung eingerichtet.](/fileadmin/_processed_/3/a/csm_DSC07173_k1_be6ce940dd.jpg)

![[Translate to Amerikanisch:] Wir begrüßen Franck Horvat bei Compass Software](/fileadmin/_processed_/4/5/csm_Compass-Software-Franck_dcec209a43.jpg)

![[Translate to Amerikanisch:] Alfred Petersen Bau- und Möbeltischlerei schließt CNC-Maschine mit Compass Software an](/fileadmin/_processed_/4/e/csm_Compass-Software-Petersen_215137e3fc.jpg)

![[Translate to Amerikanisch:] Im Rahmen eines Optimierungscoachings war unser Mitarbeiter Gereon Max beim Kunden Timmerwerken Walter Donkers in den Niederlanden zu Besuch.](/fileadmin/_processed_/8/8/csm_Compass-Software-Walter-Donkers_fafb4034f7.jpg)

![[Translate to Amerikanisch:] Unser Service Team hat bei der Firma Haas Fertigbau GmbH in Bayern eine neue SCM Maschine mit Compass Software angeschlossen.](/fileadmin/_processed_/d/3/csm_Compass-Software-Haas_7e8bb17a6a.jpg)

![[Translate to Amerikanisch:] Unser Vertriebsmitarbeiter Hermann Hasebrink stellte im April auf der Hausmesse unseres langjährigen Kunden, der Firma Meyer & Grave Treppenbau in Visbek, aus.](/fileadmin/_processed_/3/a/csm_Meyer-Grave-2018_5f8283b5cf.jpg)

![[Translate to Amerikanisch:] Compass Software Kunde Jürgen Scherner von der Firma Reuss stellte einen Tisch mit der Treppensoftware her.](/fileadmin/_processed_/3/7/csm_Vollholztisch-Treppen-Reuss_fd20990d5e.jpg)

![[Translate to Amerikanisch:] Compass Software hat einen Houfek Pfostenautomat bei der Firma K. van Sambeek B.V. in Betrieb genommen.](/fileadmin/_processed_/4/7/csm_Compass-Software-Sambeek-2_37f6f8c4e9.jpg)

![[Translate to Amerikanisch:] Unser Service hat bei unserem Kunden Jenniches Treppen aus Nordrhein-Westfalen das Compass Software Programm neu eingerichtet.](/fileadmin/_processed_/a/e/csm_DSC01625_6e0bab77a0.jpg)

![[Translate to Amerikanisch:] Starke Leistung: unsere U.S. Mitarbeiterin Milena Schäfer hat letztes Wochenende den ersten Platz bei den Georgia State Meisterschaften im Kraftdreikampf in der Gewichtsklasse 84+ kg errungen.](/fileadmin/_processed_/7/9/csm_Milena-GA-Powerlifting-800px_154d4aadec.jpg)

![[Translate to Amerikanisch:] Unser Service hat kürzlich eine weitere CNC-Maschine in der Schreinerei Eugen Schramm aus Petersberg mit Compass Software in Betrieb genommen.](/fileadmin/_processed_/c/1/csm_WP_20171113_14_23_37_Pro__highres_c475458410.jpg)

![[Translate to Amerikanisch:] Compass Software hat vor Kurzem eine CAM Installation bei unserem Kunden Przedsiębiorstwo Handlowo-Usługowe “Balsa” Spółka z o.o. in Polen durchgeführt.](/fileadmin/_processed_/0/7/csm_Compass-Software-Balsa_ffad822df3.jpg)

![[Translate to Amerikanisch:] Compass Software Vertriebsmitarbeiter Hermann Hasebrink hat einen Vortrag vor rund 25 Schülern einer Holztechniker-Klasse des Berufskolleg Beckumgehalten.](/fileadmin/_processed_/a/d/csm_Berufskolleg-Beckum-Compass-Software_e443b62499.jpg)

![[Translate to Amerikanisch:] Im Rahmen unseres 25. jährigen Bestehens, haben wir alle Compass Software Mitarbeiter zu einem exklusiven Abend im Starlight Express in Bochum eingeladen.](/fileadmin/_processed_/c/a/csm_Compass-Software-Starlight_Express_e902a5f584.jpg)

![[Translate to Amerikanisch:] Das Logo der Firma Sonnemans mit Compass Software eingefräst](/fileadmin/_processed_/2/0/csm_Logo-Sonnemans-gefraest_cfde9e6b07.jpg)

![[Translate to Amerikanisch:] Compass Software leistet nun auch Service auf Niederländisch](/fileadmin/_processed_/3/2/csm_Compass-Software-Service-Niederlaendisch_7ca3160165.jpg)

![[Translate to Amerikanisch:] Anlässlich des 25-jährigen Bestehens von Compass Software überreichte Frau Preiß von der IHK eine Ehrenurkunde als Anerkennung zum Firmenjubiläum an unseren Geschäftsführer Detlef Hollinderbäumer.](/fileadmin/_processed_/f/0/csm_Ehrenurkunde_CompassSoftware_a4da30a581.jpg)

![[Translate to Amerikanisch:] Unser Kunde, die Tischlerei Mike Altmann, hat von dem Liegenden-Krümmlings-Modul auf den CS-Krümmling aufgerüstet.](/fileadmin/_processed_/a/1/csm_Compass-Software-Kruemmling-Altmann_2df5a35a46.jpg)

![[Translate to Amerikanisch:] Compass Software Partner, die A. Falkenberg Eftf. AS aus Norwegen, feierte im Oktober 2017 ihr 125 jähriges Jubiläum.](/fileadmin/_processed_/d/f/csm_Bild_1_63bb1f1cec.jpg)

![[Translate to Amerikanisch:] Die Firma NHG UG & Co. KG aus Zetel-Neuenburg benutzt die Compass Software schon lange für den Treppenbau.](/fileadmin/_processed_/6/e/csm_Compass-Software-NHG_f6a183462b.jpg)

![[Translate to Amerikanisch:] Compass Software Inc. hat letzte Woche ein Anwendertreffen für Kunden aus den USA und Kanada veranstaltet.](/fileadmin/_processed_/0/c/csm_CS_User_Meeting_2017_86ca63b6cd.jpg)

![[Translate to Amerikanisch:] Die Franz Hasler AG aus Lichtenstein ist seit vielen Jahren Kunde von Compass Software.](/fileadmin/_processed_/5/f/csm_DSC04395_20d1d557bf.jpg)

![[Translate to Amerikanisch:] Der Kunde Shody-Horák Jiří aus Tschechien benutzt schon seit 2009 die CAD Lösungen von Compass Software. Anfang des Jahres kaufte der Kunde dann eine 4-Achs Felder Maschine.](/fileadmin/_processed_/4/7/csm_Compass-Software-Horak_02d9b5a673.jpg)

![[Translate to Amerikanisch:] An der Höheren Technischen Bundeslehr- und Versuchsanstalt Rankweil wurde neben der Compass Software Treppenbaulösung auch unsere CAM/CNC-Lösung für den Holzbau installiert.](/fileadmin/_processed_/d/0/csm_WP_20170706_16_42_28_Pro_4ac7cbd2c0.jpg)

![[Translate to Amerikanisch:] Der amerikanische Compass Software Service hat kürzlich ein Komplettsoftwarepaket bei unserem neuen Kunden H.B. Millwork Inc. in der Nähe von New York installiert.](/fileadmin/_processed_/9/0/csm_HB_Millwork_Showroom_1_3af7ebd35a.jpg)

![[Translate to Amerikanisch:] Chudzinski ist über unseren polnischen Händler seit 2008 Compass Software Kunde.](/fileadmin/_processed_/6/7/csm_WP_20170629_11_20_42_Pro_e45d69ca40.jpg)

![[Translate to Amerikanisch:] Vertriebsmitarbeiter Martin Stockhausen und Hermann Hasebrink vetraten Compass Software auf unserem Stand bei der diesjährigen AWFS Messe in Las Vegas, USA.](/fileadmin/_processed_/9/e/csm_AWFS-LasVegas_2017_80ec06d1d9.jpg)

![[Translate to Amerikanisch:] Der Compass Software Service hat im Juni bei der Firma K. van Sambeek B.V. in Holland den ersten Teil der Neuinstallation einer SCM 5-Achsmaschine erfolgreich abgeschlossen.](/fileadmin/_processed_/3/3/csm_Neue_Maschine_2017_226fffd9b9.jpg)

![[Translate to Amerikanisch:] Vertriebsmitarbeiter Hermann Hasebrink war im Rahmen der SMA (Stairbuilders and Manufacturer´s Association) National Workshop Tour bei unserem Kunden Heartland Stairways in the USA anwesend](/fileadmin/_processed_/0/4/csm_SMA-Heartland-Compass-Software_0454de0aa9.jpg)

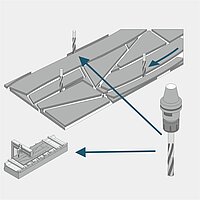

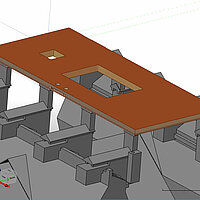

![[Translate to Amerikanisch:] Es ist jetzt möglich, mehrere CS-Krümmlinge mit Tischbelegung gleichzeitig zu bearbeiten.](/fileadmin/_processed_/b/6/csm_Tischbelegung_mit_CS-Kruemmer_a411bed450.jpg)

![[Translate to Amerikanisch:] Das Compass Software Team hat bei der Firma SAYYAS in China die 4. Maschine für den Bau von Wintergärten in Betrieb genommen.](/fileadmin/_processed_/2/4/csm_Compass-Software-SAYYAS-Wintergarten_31108b4def.jpg)

![[Translate to Amerikanisch:] Compass Software stellt auf der LIGNA 2017 aus.](/fileadmin/_processed_/3/1/csm_Ligna_2017_5856abd907.jpg)

![[Translate to Amerikanisch:] Der Compass Software Service hat kürzlich einen neuen Pfostenautomaten bei Vos Zwolle B.V. in den Niederlanden installiert.](/fileadmin/_processed_/c/6/csm_Compass-Software-Vos_4b4e4b6908.jpg)

![[Translate to Amerikanisch:] Compass Software hat über den Jahreswechsel ein neues System zur Werkstattoptimierung bei Meister-Treppentechnik (MTT) aus Bayern installiert.](/fileadmin/_processed_/8/0/csm_Compass-Software-Meistertreppentechnik-Arbeitsstationen_edd20c0732.jpg)

![[Translate to Amerikanisch:] Vertriebsmitarbeiter Martin Stockhausen stellte auch dieses Jahr wieder auf der Jahreskonferenz der Stairbuilders and Manufacturers Association (SMA) aus.](/fileadmin/_processed_/3/1/csm_Martin_Annual_Conference_SMA_f4f69a4f28.jpg)

![[Translate to Amerikanisch:] Der Compass Software Service hat eine zweite 5-Achs Maschine bei unserem Kunden Hans Konijn Houtbewerking in den Niederlanden installiert.](/fileadmin/_processed_/2/c/csm_Compass-Software-Konijn_606f122ad0.jpg)

![[Translate to Amerikanisch:] Bei der Weiterentwicklung der Compass-Treppenbaulösung arbeiten wir künftig mit der früheren Wagemeyer GmbH, Hauptkonkurrent der ersten Stunde, zusammen.](/fileadmin/_processed_/6/1/csm_Compass-Software-Wagemeyer_9bf758d756.jpg)

![[Translate to Amerikanisch:] Eva Müller hat bei Compass Software und der Fachhochschule Dortmund ein duales Studium absolviert.](/fileadmin/_processed_/b/e/csm_Compass-Software-Eva_d8d0b9079c.jpg)

![[Translate to Amerikanisch:] Der Compass Software Service hat vor ein paar Wochen eine neue Maschine bei unserem Neukunden Sobczak in Polen installiert.](/fileadmin/_processed_/4/e/csm_Compass-Software-Sobczak-PL_bb5de7db15.jpg)

![[Translate to Amerikanisch:] Letzte Woche hat der Compass Software Service erfolgreich ein neues 5-Achs Bearbeitungszentrum (Houfek) bei Neukunde Trappenmakerij Wim Van Loon in Essen, Belgien installiert.](/fileadmin/_processed_/7/5/csm_Compass-Software-Trappenmakerij_8e5e3eddd9.jpg)

![[Translate to Amerikanisch:] Compass Software Logo](/fileadmin/_processed_/4/d/csm_Compass-Software-Logo_0653dbd74b.jpg)

![[Translate to Amerikanisch:] Unser Service hat vor kurzem unsere neue Option für die Plattenoptimierung von Return Nosings bei Capital Wood Rail Inc. und JMP Wood Stairs & Rails in New York installiert.](/fileadmin/_processed_/6/8/csm_Return-Nosing-mit-Compass-Software_b0abe9640f.jpg)

![[Translate to Amerikanisch:] Der Compass Software Service hat in der letzten Woche erfolgreich eine Maschineninstallation bei der Firma Stairtech Inc. in Kanada durchgeführt.](/fileadmin/_processed_/c/8/csm_Compass-Software-Stairtech_dd427a8c1c.jpg)

![[Translate to Amerikanisch:] Die Compass Software Entwickler nahmen kürzlich an einem gemeinsamen Entwicklerworkshop teil.](/fileadmin/_processed_/1/1/csm_Compass-Software-Entwickler-Workshop_f482f7b4c8.jpg)

![[Translate to Amerikanisch:] Compass Software Kunde Schreinerei Terhalle GmbH & Co KG, hat für zwei Ihrer aktuellen Aufträge, Treppen per 3D Druck im Maßstab 1:25 und 1:100 hergestellt.](/fileadmin/_processed_/3/2/csm_Treppe-3D-Druck_94b350006f.jpg)

![[Translate to Amerikanisch:] Vertriebsleiter Klaus Eilers hat bei der Hausmesse der Firma Papenbroock (28.10 - 30.10.2016) ausgestellt.](/fileadmin/_processed_/a/3/csm_Papenbroock-Hausmesse-2016_4a8f57424f.jpg)

![[Translate to Amerikanisch:] Compass Software auf der W16 in Birmingham, UK.](/fileadmin/_processed_/a/f/csm_W16_28b190cab2.jpg)

![[Translate to Amerikanisch:] Compass Software Inc. auf der IWF 2016 in Atlanta.](/fileadmin/_processed_/0/5/csm_Compass-Software-IWF16_e9aa3bf711.jpg)

![[Translate to Amerikanisch:] Compass Softwares neuer U.S. Servicemitarbeiter Steven Chiu hat seine erste Schulung bei WH Stairs in Chicago durchgeführt.](/fileadmin/_processed_/1/0/csm_Compass-Software-WH-Stairs_8c72dd8a1f.jpg)

![[Translate to Amerikanisch:] Sales and Marketing Representative Milena Schäfer hat die neuen Mitglieder der deutsch-amerikanischen Handelskammer Süd bei der diesjährigen New Member Reception in Atlanta begrüßt.](/fileadmin/_processed_/d/4/csm_New_Member_Reception_GACC_South_2016_collage_83f8e467c4.jpg)

![[Translate to Amerikanisch:] Martin Stockhausen hat auf dem jüngsten Workshop der SMA Nationwide Tour bei King und Company Architectural in Keene New Hampshire ausgestellt.](/fileadmin/_processed_/b/0/csm_SMA-Keene-NH-Martin_cc5fe9629c.jpg)

![[Translate to Amerikanisch:] Die Bearbeitung der Handlaufteile (cappings, volutes, goosenecks, easings) ist jetzt vollständig in den aktuellen Compass Software CNC Prozessoren integriert.](/fileadmin/_processed_/f/8/csm_Software-GTA_00526b6c23.jpg)

![[Translate to Amerikanisch:] Vertriebsmitarbeiter Hermann Hasebrink hat in der letzten Woche unseren chinesischen Händler auf der WoodExpo in Shanghai unterstützt.](/fileadmin/_processed_/a/5/csm_Wood_Expo_Shanghai-Compass-Software_d4b2c14f7b.jpg)

![[Translate to Amerikanisch:] Compass Software Service Mitarbeiter Alexander Dörr hat seinen ersten Wintergarten-Postprozessor für einen unserer Kunden in China erfolgreich installiert.](/fileadmin/_processed_/3/2/csm_Compass-Software-Wintergarten-China_2759518d40.jpg)

![[Translate to Amerikanisch:] Compass Software Inc. Mitarbeiter Steven Chiu. Technical Customer Service Specialist.](/fileadmin/_processed_/3/7/csm_Compass-Software-Steven_0219d2d66d.jpg)

![[Translate to Amerikanisch:] Compass Software meldet bestes Geschäftsjahr der Firmengeschichte.](/fileadmin/_processed_/5/4/csm_Bestes_Geschaeftsjahr_Compass_Software_b988ac1dff.jpg)

![[Translate to Amerikanisch:] Milo, Anti-Stress Beauftragter bei Compass Software.](/fileadmin/_processed_/e/d/csm_Compass-Software-Milo_0498992257.jpg)

![[Translate to Amerikanisch:] Samir Rabbasy, Entiwcklungsteam. It-Fachinformatiker und Anwendungsentwickler.](/fileadmin/_processed_/2/5/csm_Compass-Software-Samir_ab7c94e4c1.jpg)

![[Translate to Amerikanisch:] Letzte Woche, hat unser Vetriebsmitarbeiter Jürgen Gerdt an der offenen Tür Veranstaltung von SCM UK in Nottingham teilgenommen.](/fileadmin/_processed_/5/1/csm_SCM_Maschine_b66b2a672c.jpg)

![[Translate to Amerikanisch:] Mitarbeiterin Milena Schäfer im neugegründeten Büro in Atlanta, Georgia.](/fileadmin/_processed_/f/a/csm_Compass-Software-Milena_in_ATL_dd852793c5.jpg)

![[Translate to Amerikanisch:] Unsere CAM/CNC-Softwarelösung für den Holzbau wurde als BEST OF für den INNOVATIONSPREIS-IT 2016 ausgezeichnet.](/fileadmin/_processed_/7/b/csm_Compass-Software-BEST_OF_Innovationspreis_4cbfe0feef.jpg)

![[Translate to Amerikanisch:] CAM-Timber – unsere CAM/CNC-Softwarelösung für den Holzbau – wurde für den INNOVATIONSPREIS-IT 2016 qualifiziert!](/fileadmin/_processed_/3/b/csm_Compass-Software-Innovationspreis-IT-Qualifiziert_926ade08d1.jpg)

![[Translate to Amerikanisch:] Compass Software auf der WMS 2015 in Toronto, Kanada](/fileadmin/_processed_/3/9/csm_Compass_Software_WMS_2015_1413de7e4d.jpg)

![[Translate to Amerikanisch:] Bei der Fa. Keller in der Schweiz wurde kürzlich der neue Abbund-Prozessor der Compass Software GmbH in Betrieb genommen.](/fileadmin/_processed_/f/9/csm_Compass-Software-Keller-BTL-Prozessor_b4a7c6922a.jpg)

![[Translate to Amerikanisch:] Die Fa. VIOS Trappen hat sich dazu entschlossen, in Zukunft die komplette Fertigung von mehr als 15.000 Treppen/Jahr von der Compass Software GmbH steuern zu lassen.](/fileadmin/_processed_/c/5/csm_Compass-Software-VIOS_1da45da4f0.jpg)

![[Translate to Amerikanisch:] Um besser auf den sehr wichtigen Markt reagieren zu können, hat CS im Februar 2015 eine Niederlassung in den USA gegründet.](/fileadmin/_processed_/4/9/csm_Compass-Software-USA_94aad798e2.png)

![[Translate to Amerikanisch:] Seit kurzem kann man den Compass Software Treppenkonfigurator auch auf dem Treppenportal treppen.net finden.](/fileadmin/_processed_/6/1/csm_www_treppen_net_ad8a2db7df.jpg)

![[Translate to Amerikanisch:] Compass Software auf der LIGNA 2015](/fileadmin/_processed_/2/6/csm_Compass-Software-Ligna-2015_2efd5048e9.jpg)