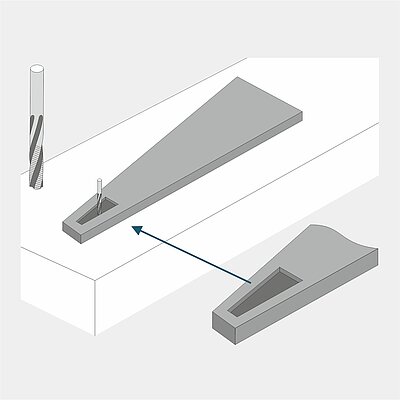

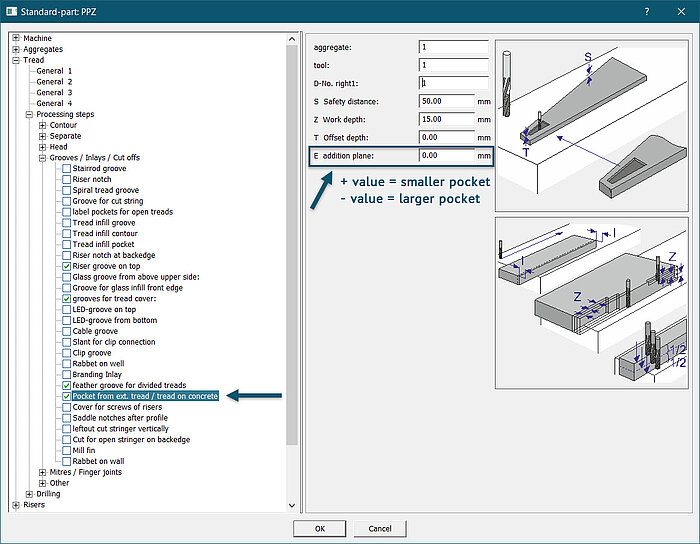

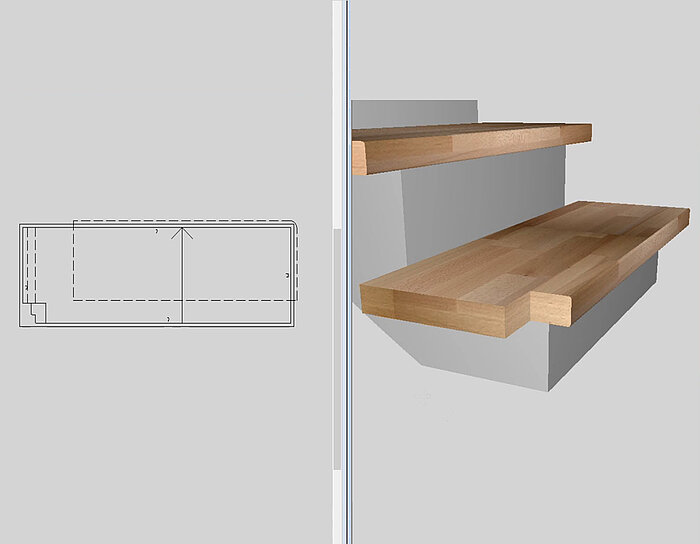

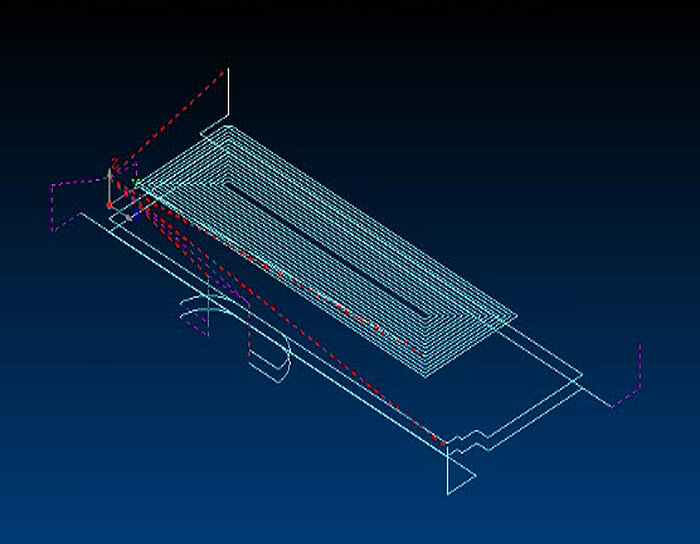

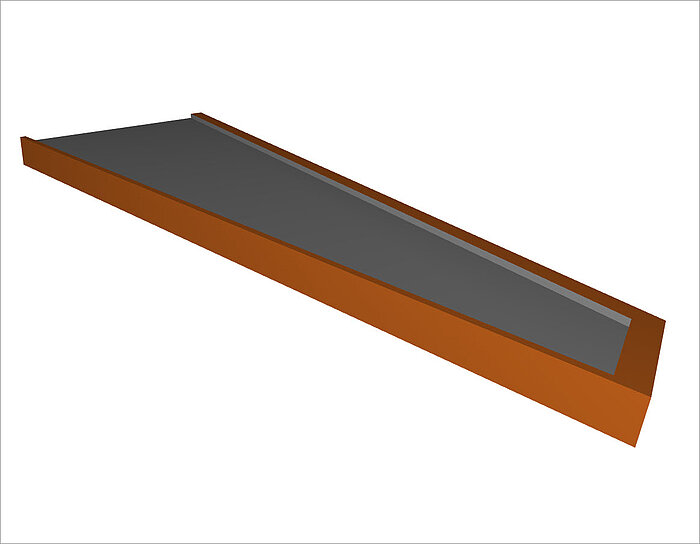

The function “addition plane” allows customers to increase the size of pockets on the underside of treads that are to be placed on top of the concrete core. When cutting these pockets, the shape of the CNC tool results in rounded corners on the pockets. Previously, if the pocket was to fit perfectly onto the concrete core tread below, the stair builder would have to manually re-cut the tread corners to make them sharp enough to fit on the corners of the concrete core. Now, the pockets can be cut larger, and the tread will fit onto the concrete core below even if the corners are rounded. Furthermore, it is possible to even out small imperfections in the concrete core this way. This saves time and effort.

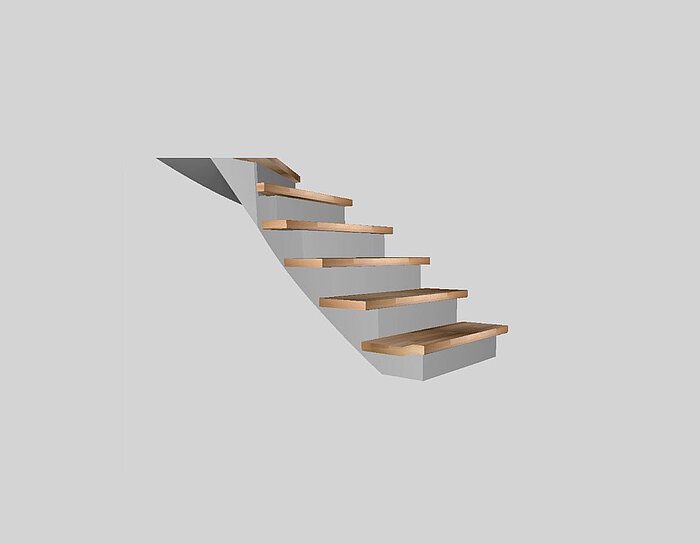

Larger Pockets for In-Situ Concrete Stairs