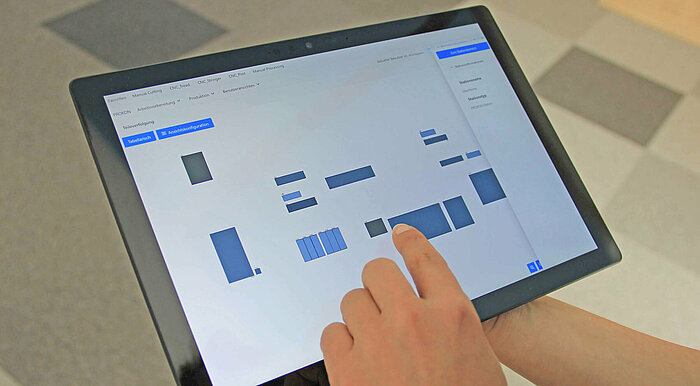

Our MES solution PROKON can gradually lead any business into the future, due to the application of the newest development techniques. The MES software can be scaled individually to fit any size of production. The MES system features an intuitive and flexible user interface and a multitude of manual intervention possibilities on different levels for all users.

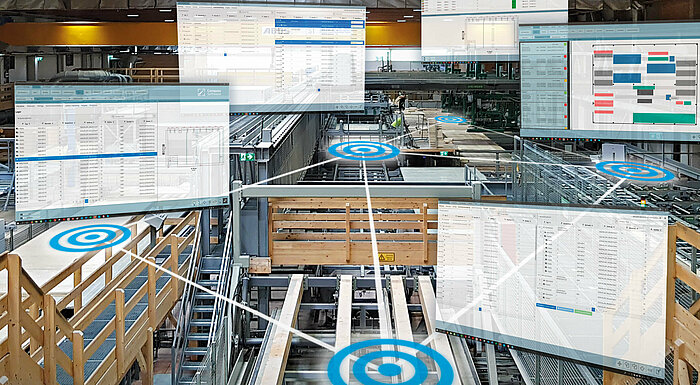

The MES Software can be connected seamlessly with our stair building software and timber solutions. Furthermore, it is possible to link the MES solution with external systems at every point during production. Potential existing software solutions are CAD systems, ERP systems, CRM systems, BDI systems, warehouse management systems, dispatch warehouse management systems, and much more. The respective interfaces are XML, BTL, BVX, DXF, IFC, etc. Additionally, it is possible to issue commands or exchange information via hardware interfaces, such as OPC or HMI.

![Compass Software [Translate to Amerikanisch:] [Translate to Englisch:] MES System von Compass Software](/fileadmin/_processed_/9/4/csm_MES-Stationen-vernetzt_a9517e8c42.jpg)

![Compass Software [Translate to Amerikanisch:] [Translate to Englisch:] MES Stationen](/fileadmin/_processed_/2/a/csm_MES-Stationen-Compass-Software_d3a6ae2f6b.jpg)

![[Translate to Amerikanisch:] [Translate to Englisch:] Jürgen Alber, Inhaber der Alber Treppensysteme GmbH](/fileadmin/_processed_/b/f/csm_Compass-Software-Alber_01_22883f29f1.jpg)

![Compass Software [Translate to Amerikanisch:] [Translate to Englisch:] MES Status](/fileadmin/_processed_/1/b/csm_MES-Status_0d025fa9f9.jpg)

![Compass Software [Translate to Amerikanisch:] [Translate to Englisch:] MES-Bauteilgruppen-Monitor](/fileadmin/_processed_/3/1/csm_MES-Bauteilgruppen_ec308aa90d.jpg)

![Compass Software [Translate to Amerikanisch:] [Translate to Englisch:] MES-Monitor-Kontrolle](/fileadmin/_processed_/c/9/csm_MES-Kontrolle_2a77473d3c.jpg)

![Compass Software [Translate to Amerikanisch:] [Translate to Englisch:] MES Kommissionierung](/fileadmin/_processed_/6/6/csm_MES-Kommissionierung-2_363dcad171.jpg)

![Compass Software [Translate to Amerikanisch:] [Translate to Englisch:] MES Kommissionierung](/fileadmin/_processed_/a/2/csm_MES-Kommissionierung_8ed38514b3.jpg)

![Compass Software [Translate to Amerikanisch:] [Translate to Englisch:] MES Kommissionierung](/fileadmin/_processed_/f/7/csm_MES-Kommissionierung-3_b398dd5cd6.jpg)

![Compass Software [Translate to Amerikanisch:] [Translate to Englisch:] Just-in-time Fertigung bei Compass Software Kunden DeVries](/fileadmin/_processed_/d/c/csm_de-vries5-praxisbeispiel-compass-software-dortmund_9d8aaffc32.jpg)