Innovative CAM/CNC Software Solutions for Mass Timber Construction

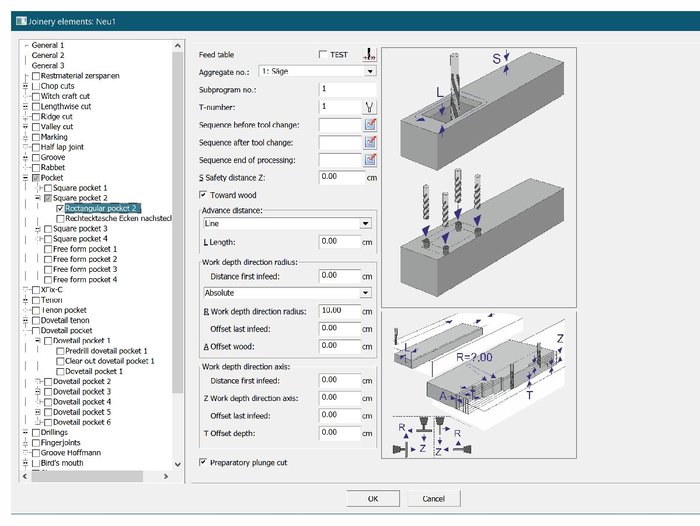

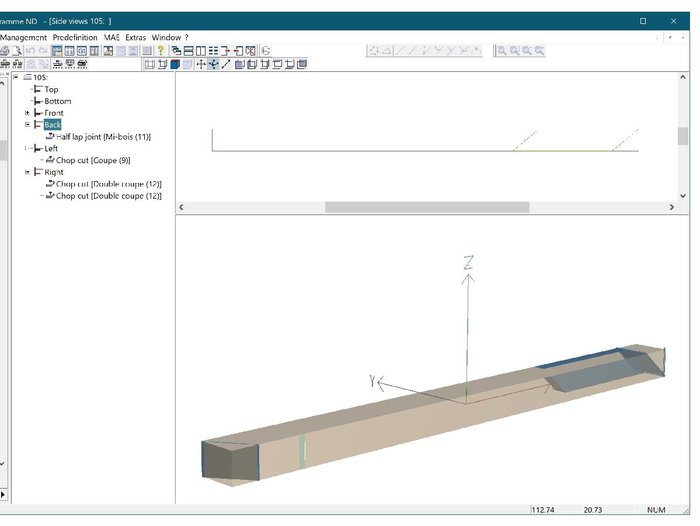

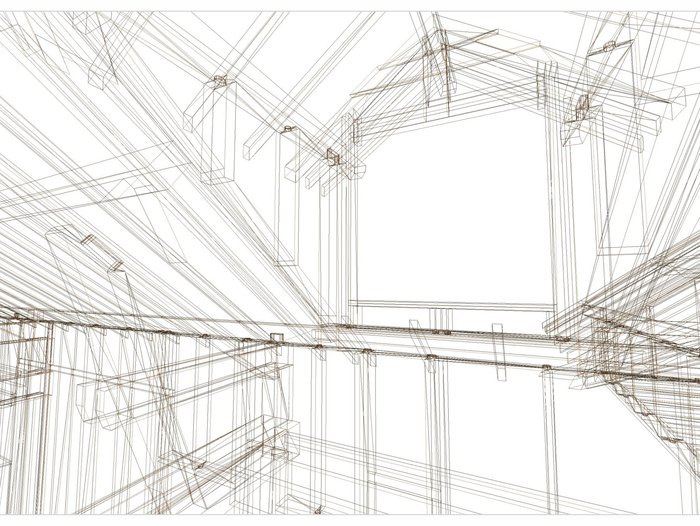

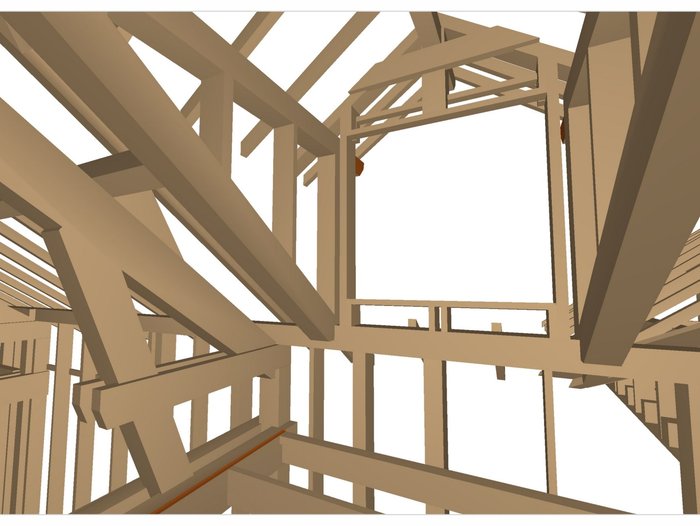

Next to our flexible and highly precise solutions for stair manufacturing, we also offer CAM (Computer Aided Manufacturing) solutions for timber construction. These are based on various interfaces that are serviced by all common timber design software. Our CAM module is highly flexible, network compatible, and allows for an unlimited number of machine-axes. The control of units with 5 axes in one head is standard practice and makes three dimensional interpolated processing possible. We also offer coupled application of loading systems, such as feeding systems and robots. The most important goal of our software is to make sure that customers have as little to do with the programming of the CNC machine in their daily operations as possible. To ensure this our software automatically generates processing programs for all parts on the CNC machine.