The family company Carpentry Burfeind GmbH from Hamersen, Germany produces pretty much anything a carpenter can do, from plastic window frames over wood windows, doors, furniture, and stairs. Since 2018, the carpentry has been utilizing a HOMAG BMG 311 with 5 axes.

Up until now, the company had been using DXF drawings and designs of stair parts from another Compass Software customer. They bought the individual drawings and produced them with their Homag CAD/CAM software manually. This process took up a lot of time and was tedious.

Daniel Burfeind remembers: “Back then, I had to program for up to 2 days to finish all the work processes for the machine. The stair business is so lucrative right now that I cannot invest this time anymore.”

Thus, the carpenter decided to purchase the Compass CAD/CAM stair software himself at the end of January 2021.

You can read the entire case study in PDF format here:

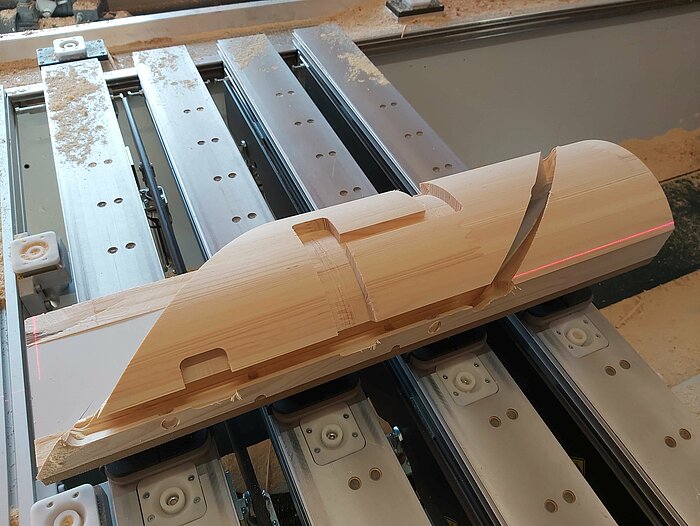

![Compass Software [Translate to Amerikanisch:] Homag CNC machine at Burfeind GmbH controlled by Comapss Software](/fileadmin/_processed_/8/2/csm_Kruemmer_auf_der_CNC_Maschine_a882d60876.jpg)

![[Translate to Amerikanisch:] Daniel Burfeind](/fileadmin/_processed_/2/d/csm_Daniel_Burfeind_01_2fec0f31f9.jpg)

Back in the day, I had to program for up to 2 days to finish all the work processes for the machine. The stair business is so lucrative right now that I cannot invest this time anymore. The contingent is perfect for us. It allows us to use the complete CAD design and CNC production for a smaller price.

Daniel Burfeind

Stair Contingent: Complete Software Solution for a Smaller Price

Since stair building is only one part of Burfeind´s larger product offering, the company decided to purchase a Compass Software stair contingent. This option of the stair building software allows customers to only buy a certain allotment of CAD/CAM stair designs and production output per year. Contingent customers do not have to invest in the entire software. The number of stairs included in the contingent is negotiated with the sales department on a case-by-case basis.

The machine, tools, and machine operation equipment were all found in top condition on-site. The cooperation between the carpentry team and the Compass Software technician was great. The software could be installed fast and without problems. We are happy that Carpentry Burfeind GmbH (www.burfeind-gmbh.de) is now a full Compass Software customer and that they can save valuable time with our solutions.