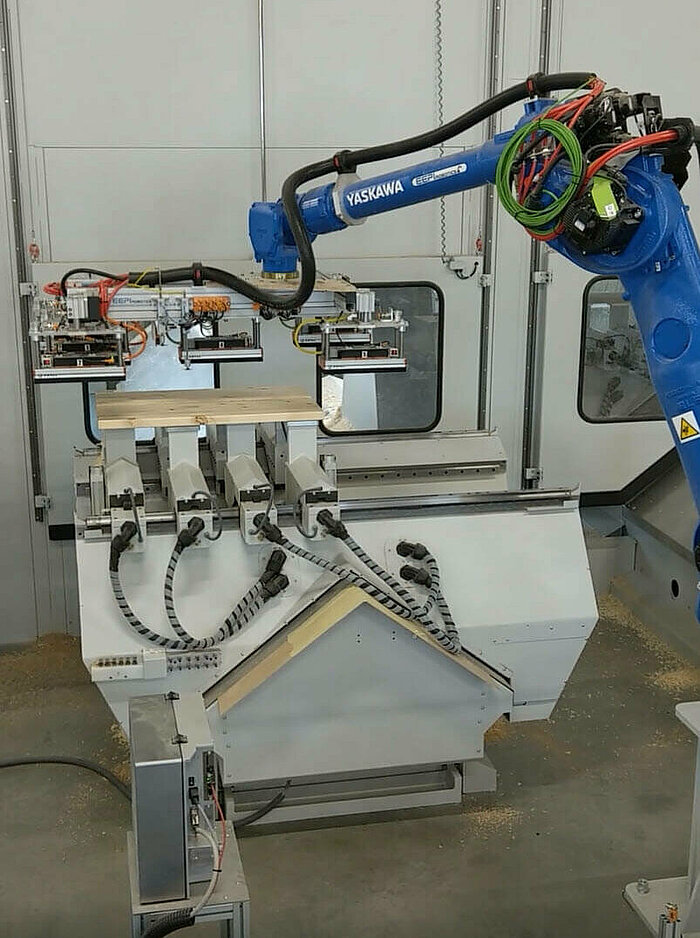

The Reichenbacher ECO B has been equipped with a robot that autonomously loads plates onto the machine tables. During this action, the robot scans the plate barcode, automatically retrieves the required CNC code from Compass Software, decides by itself which machine table will be available next, and transports the plate to the respective machine side. Once, the processing on the machine has been finished, the robot labels the completed treads and takes them off the machine. Subsequently, the cycle starts over, and the robot loads a new plate onto the machine. This process ensures a continuous unsupervised production.

The Reichenbacher ECO B processes components parallel on two tables with alternating processing. That is a plate enters the machine on one side and is sawed into two pieces. Next, the machine table separates, and the tread combination can be processed parallel on two stations at the same time. The machine cuts all waste material into small pieces so that they will not be stuck on the clamping device of the machine, which in turn saves immense time that does not need to be spent on completely chipping the waste material. Treads can be sawed, profiled, and smoothed. Once the tread is finished completely, the machine unit switches to the other side of the machine and starts processing the next tread combination. Meanwhile the finished treads are transported out of the machine where the robot takes them off the machine and stacks them up. The alternating processing on four stations is an enormous time saver and increases the efficiency of the stair builder.

The Aru Grupp AS has fully entered IoT processing (Internet of Things) thanks to the automations with Compass Software. The machine can finish components completely and autonomously. That saves time and increases efficiency. We are looking forward to completing further optimisations and to implement the door production on the machine.