The Dutch stair manufacturer Trappentoko was founded by Jeffrey Pels in 2009. Jeffrey had already been working in the stair business for many years before but decided to try to grow a successful business on his own. In 2009 he started installing stairs for other stair manufacturers with just a van and some tools. Since then, he has grown his business in the most impressive way.

After only 2 years of installing stairs, Jeffrey was able to rent his own workshop and start building stairs by hand with the Compass Software CAD solution and a plotter. Whitin a year, bought an old second-hand CNC machine, which he also operated with Compass Software. The purchase of the machine necessitated the hiring of two employees, whom Jeffrey knew from a former employer and who are still working for him now.

Today, Trappentoko employs 17 workers and operates 3 brand new CNC machines in a modern workshop with a sleek looking office building. The stair company went from producing about 10 stairs a week to averaging some 70 custom design staircases every week these days. The workshop is highly efficient and ready to grow more in the future.

25% More Orders without Having to Raise a Finger

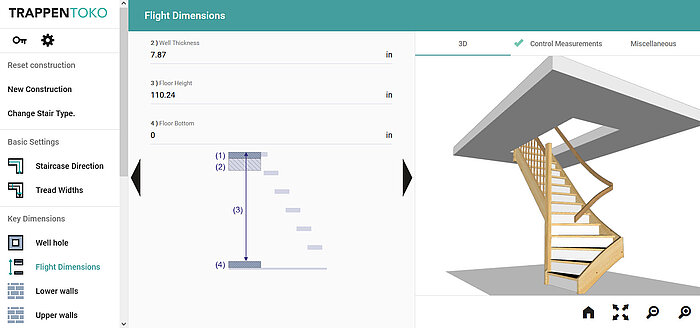

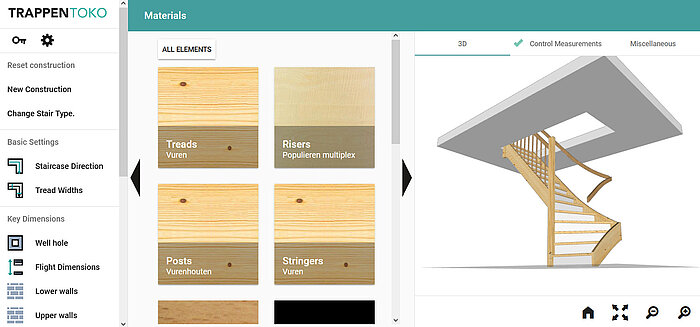

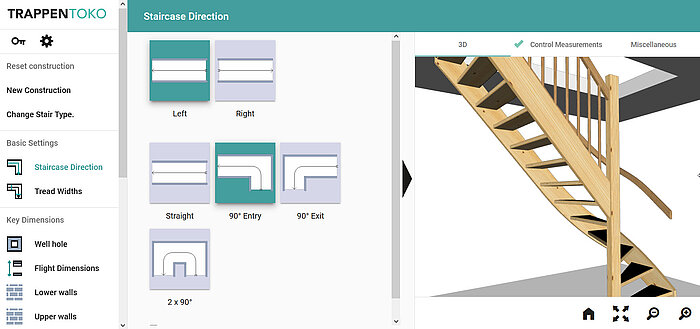

Next to the machines itself, Trappentoko also utilizes powerful software solutions for design and acquisition of end-customers. The company uses the Compass Software Staircase Configurator, which is available on Trappentoko´s website. The Staircase Configurator is an online tool that lets end-customers design their own stairs on any internet browser. On the backend side of the online tool, Jeffrey gets to decide what components of stairs should be available to customers, e.g., which handrail and baluster styles the customer gets to choose from or what shape of stairs are available. The customer then goes through several steps online to design their own stair, which they can visualize in 3D in real-time.

Our end-customers really love designing their own stair. You can do it with cars and furniture, and now you can also do it with stairs. Since using the Staircase Configurator, we generate about 20-25% more requests, without having to put any work into the acquisition of those customers.

Jeffrey Pels - Owner

Once the customer finishes the design the stair, Trappentoko can generate an XML file from the offer request, which they import into their ERP software to generate a precise quote for the customer. The configurator enables them to generate quotes faster and more precisely. Furthermore, the customer´s design can also be imported straight into the Compass Software´s CAD interface. Trappentoko´s designers only have to check the data for accuracy and make minor tweaks before the staircase can be exported for CNC processing. This saves an enormous amount of time, which would usually have to be spent going back and forth with customers on design questions and perfecting the CAD drawing. And since time is Trappentoko´s most valuable asset, the tool has become invaluable to them. It frees employees up to provide better customer service and take on more orders.

Significant Savings in Time with Modern Machinery

As mentioned above, Trappentoko started out with old second-hand machines, but as business picked up more and more, Jeffrey was able to replace the old machines with brand new CNC machines that offer more and better possibilities. Today, Trappentoko has 3 machines which he controls with Compass Software´s multitude of CAM solutions.

The first machine is a 2018 SCM Accord 25 fx with 3 axes. This machine is used exclusively to produce treads. The CNC has two machine tables which make alternating processing possible, that is while the machine is processing treads on one table, the machine operator can unload finished treads on the other and load new material onto the machine. The machine has dual motors which save time during tool changes. This way the machine is constantly working on alternating sides with no down time.

Overall Trappentoko was able to increase efficiency by about 20% with this machine. But because treads were now processing 20% faster than the other components Trappentoko also had to replace their other machines to keep up with the speed.

The second machine in the workshop is a 2021 SCM Accord 25 fx with two motor units, automated vacuum cups, and 5 axes. Due to the number of axes the stair builder can run any stair part on this machine. The dual motors save significant time during tool changes and the automated vacuum cups match the 20% savings in time which the tread machine offered.

The third machine Trappentoko operates is a 2021 Morbidelli N100, a nesting machine with 3 axes.

Our nesting machine results in about 10% savings of material, which is great, but the best thing about the nesting machine is that we have completely eliminated errors that resulted from manual nesting. Before, our workshop employees had to cut risers by hand and sometimes the riser ended up a little too long or a little too short. Once we got to the building site, the customers often noticed the discrepancies. We do not have any errors in our risers anymore. Before, I had one employee who did nothing but risers all day. Now, he can finish the day´s risers in only a few hours and he can be utilized on other workstations the rest of the day.

Jeffrey Pels - Owner

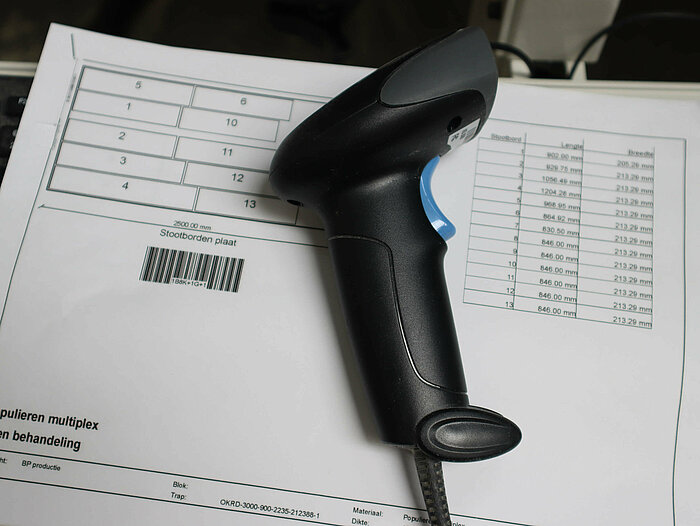

Efficient Data Transfer through Barcodes

Trappentoko´s entire production is organized via the Compass Software barcode solution. All machines are equipped with barcode readers which scan identification barcodes on the individual components. Before switching to barcode technology, the machine operators had to extract the processing data from USB drives. Every time an error occurred the operator had to take the USB drive, go to the office, correct the error in the code, put the new code back onto the USB, and walk back to the machine. This took up a lot of time. Now, the stair builder has much more flexibility, the code can be read and edited straight on the machine and the information in the barcode is changed simultaneously.

Trappentoko´s Trick for Getting Around Worker Shortages

Everywhere you look these days, you hear about shortages of skilled labor. However, Jeffrey Pels does not have any problem finding workers for his stair shop. His recipe for success is keeping it simple, in-house training, and exceptional worker retention. Trappentoko welcomes workers from all around the world. Jeffrey and his senior employees train new additions themselves. Thus, workers do not necessarily have to have previous experience to start a successful career in the workshop. The stair builder uses modern technology, such as barcodes to keep things simple. The machine operators do not have to understand every single line of code to process components. Although, Jeffrey assures, he is happy to teach anyone who is interested and some of his employees know the CNC code “better than he himself” by now, he admits laughing.

Next to accepting a diverse group of applicants, Jeffrey also employs several workers from a local organization that houses people with disabilities. Trappentoko offers internships at their workshop and if the applicants like the work there they are hired full time. So far, the stair builder only had one person who did not want to stay beyond their internship. All in all, Jeffrey Pels has a great relationship to his employees and creates an enjoyable working climate which results in extremely high worker retention and worker satisfaction.

Compass Software the Best Partner in Stair Building

Jeffrey Pels has been relying on Compass Software since the founding of his own company. He would recommend Compass Software to anyone who is looking for a strong partner in the stair building sector. It has helped him grow exponentially in the last decade.

I knew Compass from my former employer, and I was convinced it would be the best solution for me as well. Of course, I shopped around before making my final decision. I was in contact with competitors, but I have to say I immediately had that personal connection with the people at Compass Software. I just had a good feeling about it. That is why I went with Compass Software.

Jeffrey Pels - Owner

The Next Step: Doubling Production As Soon As Possible

Even through Trappentoko has grown from producing only 10 staircases a week to 70 custom build staircases each week in only a little over one decade, Jeffrey Pels is far from done. “I want to double the company. I am looking for a suitable space in the region. Ideally, I want to have a second production line with an additional 3 CNC machines. Then we could export our custom-made staircases to France, Germany, and maybe even some other countries. I am ready for the next step, as soon as I find the right space.”