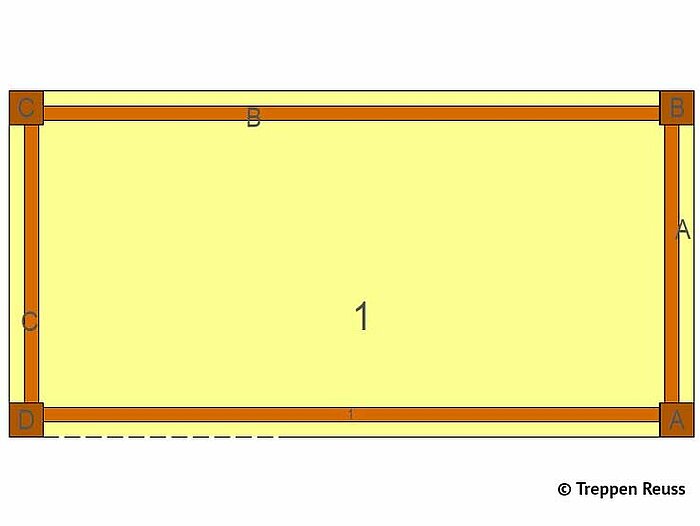

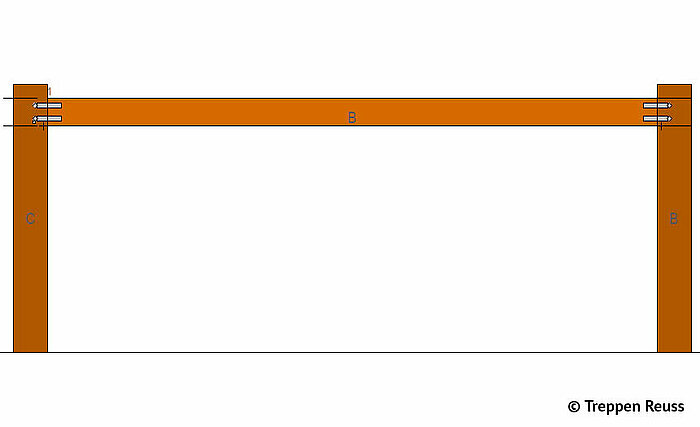

Since the design worked so well with the software, the stair builder decided to take it one step further: he used the drilling patterns in the height construction and was able to build in the necessary connections between the parts. Sending everything through the post-processor to the MAKA FPM 470 R CNC machine, which was installed by Compass Software technician Ralph Linnemann, was only the cherry on top. The generation of the CNC code went smoothly, just like with any staircase. After a few moments the CNC codes for milling were ready. Surprised by the success of this project, Mr. Scherner is already thinking about other application possibilities for the staircase software.

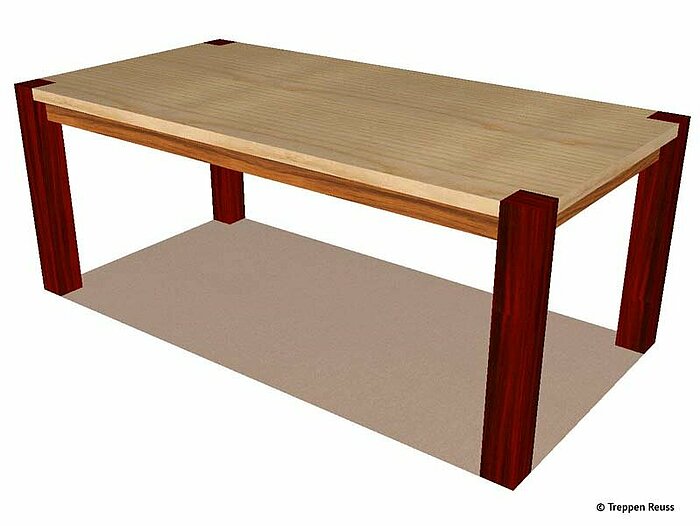

We want to thank the company Reuss for this brilliant idea and the pictures they have provided us with.

General

Reports

General

Reports