© Deluxe Stair and Railing

© Deluxe Stair and Railing

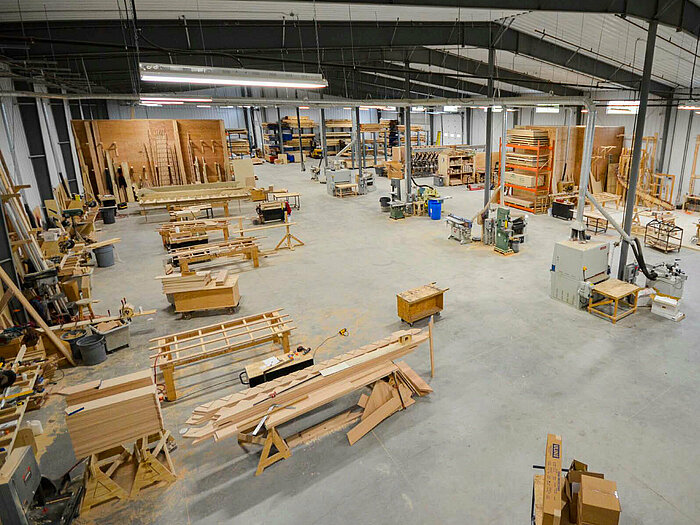

Deluxe Stair and Railing is a Toronto based woodshop that started out three decades ago with only one man and a garage. Founder Joe Morra was proudly handcrafting stairs and eventually secured a loan to open a 1,500 square foot facility in Pickering, Ontario in 1997. Between then and now, much has changed at Deluxe Stair and Railing.

The company has built their own 25,000 square feet woodshop on the Stouffville-Uxbridge border, which was completed in early 2019. These days Deluxe Stair is run by Joe´s son Jesse Morra and the family business employs 25 people. Of course, Joe is still involved with the business as well. Next to the size of the woodshop, the company has also invested in making their operation modern and efficient. Part of this modernization was the purchase of a CNC machine and stair building CAD/CAM software.

Here you can download the case study as a PDF:

We can router about a rise a minute with Compass and the SCM. So, if we have a 16-rise stair, it will be finished in about 16 minutes. This would have taken at least three-times as long before. The advantage of the machine is that every rise is exactly the same. If you have people working by hand, there will always be a little variation on size, depending on how they laid out the wood to measure. But, since using Compass Software, we have been able to keep the quality of stairs high and uniform.

Ryan Blyth - CNC Coordinator

Three Times More Productive with Up To 50 Stairs a Week

After visiting the WMS, Canada´s biggest woodworking trade show in Toronto, and seeing what Compass Software could offer, Jesse and Joe became interested in stair building software for their operation. Still, it was not until late 2017, after the purchase of their 3-axis SCM Pratix Z2 that Deluxe Stair finally installed and implemented Compass Software in their woodshop.

Ryan Blyth, CNC Coordinator at Deluxe Stair proudly pronounces: “Since implementing Compass Software, we easily produce three times more than before. We have three people who only work with Compass Software. Two who do the CAD design and one who works on the CNC machine. This way we are able to produce 30 – 50 stairs a week.” Because of the high demand and capabilities Deluxe Stair was even able to double their carpenters from three to six, which enables them to produce more stairs than ever before.

Peace of Mind Production through Software Safety Features

One of the things the stair builder appreciates the most about using Compass Software is the peace of mind it gives him. The team has saved different program templates for different kinds of stairs in Compass Software. Thus, once the design process is done, all they have to do is select the CNC program for that type of stair and the software automatically selects all the right bits to router the stair. The process is fast and easy, and the user does not have to program every single component themselves.

What I appreciate the most are the safety measures that are included in Compass. When we still used to program the SCM ourselves, we had to make sure every time that there would be no problems during processing and that takes a lot of time and precision. The risk for human error was high. Compass automatically checks each CNC program for safety, which makes it save to use with multiple users.

Ryan Blyth - CNC Coordinator

Bright Future and Further Expansion

In the case that some questions do arise during the design and processing of the stairs, Ryan is happy he can rely on Compass Software´s US support. Compass Software Inc. Service Technician Steven is always very fast, responsive and helpful. Ryan concludes that he would recommend Compass Software to any stair builder, although he remarks laughing: “I would absolutely recommend it, unless it´s our competitors, then I´d rather they don´t use it.” The stair building software has given Deluxe Stairs a significant competitive edge over other stair builders in the area. It has made Deluxe Stair and Railing faster, more precise, and more productive. Now they are even thinking about purchasing another machine for making tread posts and components. We are looking forward to seeing Deluxe Stair continue to grow and be a reliable partner alongside their journey.

© Deluxe Stair and Railing

![Compass Software [Translate to Englisch:] Roboter bei Trappen Verschaeve](/fileadmin/_processed_/8/8/csm_DSC_0981_0bc3af92cf.jpg)