From Handcrafting to Automation: A Journey with Compass Software

Aru Grupp’s origins trace back to 1991 when the company was initially established by two brothers-in-law turned entrepreneurs as a farming business and shortly after an additional sawmill. However, they soon realized that these industries were highly seasonal, with significant slow periods in the winter months. To address this challenge, they looked for additional ways to utilize their materials and workforce during the off-season. This led to the expansion into window and door manufacturing, which provided a steady revenue stream year-round. As demand grew, the company further diversified into stair production in 1996, initially crafting each stair by hand.

By the early 2000s, stair production had become a key pillar of Aru Grupp’s business. The transition from manual production to automation was driven by growing export demands and the need for increased efficiency. To scale effectively, Aru Grupp sought a software solution that could seamlessly integrate into their processes while optimizing production. The team first encountered Compass Software at Ligna, a German trade show, leading to a long-term collaboration that revolutionized their production process.

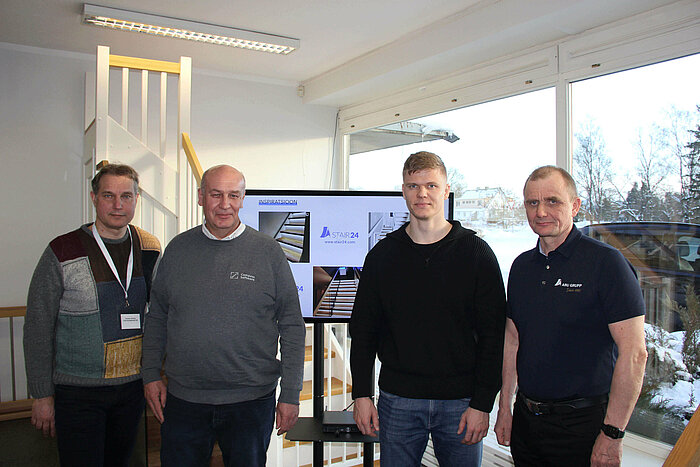

Juhan Viise (right), owner of Aru Grupp, with son Johannes

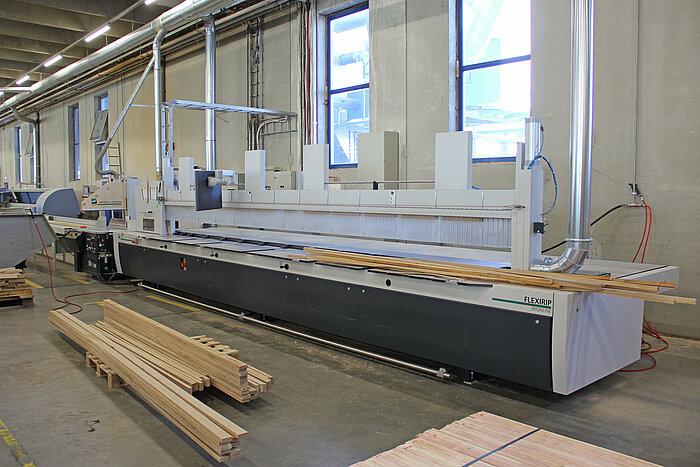

For the first two years, Aru Grupp utilized Compass Software solely for CAD design while continuing to construct stairs manually. As the business expanded, they began investing in CNC machines to increase efficiency. Over the last 15 years, the company has grown significantly, increasing its stair building turnover by over 600 % - from 1 million to 7.3 million. Today, Aru Grupp operates in their staircase production eight CNC machines from various manufacturers, all controlled by Compass Software. This transition has enabled the company to scale its operations efficiently without compromising on quality. “The biggest advantage of Compass Software is that we are not limited to one machine manufacturer,” explains Juhan Viise, owner of Aru Grupp.“ This allows us to select the best equipment for each specific task, ensuring maximum efficiency.”

The biggest advantage of Compass Software is that we are not limited to one machine manufacturer. This allows us to select the best equipment for each specific task, ensuring maximum efficiency.

Juhan Viise - Owner

Seamless Integration and Reliable Performance

A key advantage of the software is its ability to integrate seamlessly with various CNC machines, eliminating compatibility issues and ensuring uninterrupted production. “After an initial trial period of about six months, we experience very few errors,” Juhan notes. “Compass Software allows us to operate multiple machines seamlessly, which significantly boosts our efficiency.”

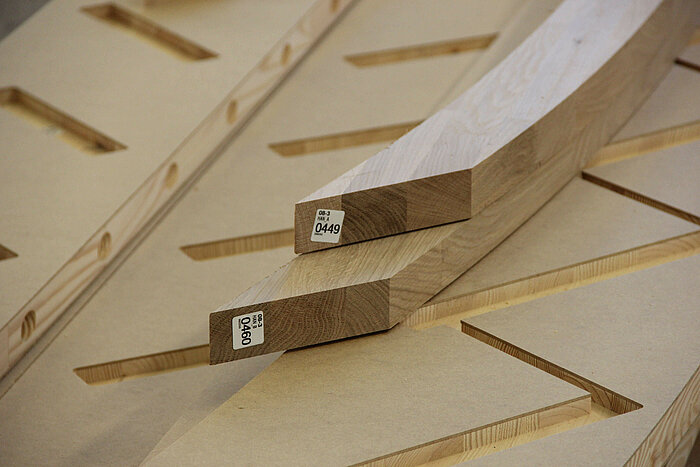

Beyond efficiency, the use of advanced CNC software also enhances precision in manufacturing. Its advanced algorithms help reduce material waste and optimize cutting strategies, resulting in cost savings and improved sustainability. With accurate data tracking via RFID chips in all stair parts and real-time production insights, Aru Grupp can maintain a high standard of quality while minimizing errors and delays.

Aru Grupp's collaboration with Compass Software’s Estonian dealer, Urmas Jüriorg from Cadsys, has been instrumental in ensuring continuous support and system optimization. The company values the high level of expertise and professionalism delivered by Compass Software's sales, development, and service teams. “What I appreciate most about Compass Software is the people,” Juhan says. “Every interaction, whether in sales, development, or service, has been outstanding.”

From left to right: Urmas Jüriorg (Cadsys), Martin Stockhausen (Compass Software), Johannes Viise and Juhan Viise (Owner Aru Grupp).

Expanding Global Reach with a Smart Business Model

Aru Grupp’s success is built on strong international partnerships. The company exports up to 57% of its staircases to key partners in the Netherlands, Denmark, Norway, and Sweden, along with other markets as distant as Canada and Japan. With Compass Software, Aru Grupp can accommodate the varying stair styles and requirements of its global partners and is able to cover 95% of all design and production requirements with just one software. Smaller stair businesses benefit from this system, as they can send their stair designs directly to Aru Grupp for production, ensuring precision and efficiency. “We help our partners grow, and as they grow, so do we,” says Juhan.

Aru Grupp goes beyond manufacturing by actively supporting small stair businesses in both production and installation. Whenever they onboard a new partner, they strongly recommend using Compass Software. This ensures seamless integration, as designs can be directly imported into Aru Grupp’s system for production. By making it easier for smaller businesses to expand their operations, Aru Grupp helps them establish a stronger market presence. As these businesses grow, their demand for stair production increases, creating a win-win situation where both parties benefit. This collaborative approach fosters long-term business relationships and strengthens Aru Grupp’s position as a key industry player.

The company’s Stair24 web-platform, launched in 2020, further enhances accessibility by allowing end customers to design their stairs online. This digital approach streamlines the order process, making high-quality stair production more efficient and customer-friendly.

Compass Software is one of our most valued partners. The software's flexibility, reliability, and strong support network make it an essential part of our business. Every interaction, whether in sales, development, or service, has been outstanding.

Juhan Viise - Owner

A Thriving Work Environment

Beyond technology, Aru Grupp fosters a supportive and inclusive work culture. Employees enjoy a friendly atmosphere, daily company-sponsored lunches, and a management team that values personal connections. Unlike many woodworking companies, Aru Grupp employs a high percentage of women, further diversifying its workforce. Juhan Viise personally knows all his employees, creating a close-knit, collaborative environment that translates into high morale and strong team performance.

A Reliable Partnership for the Future

Looking ahead, Aru Grupp continues to leverage Compass Software to maintain its competitive edge. The software’s capabilities in machine integration, production planning, and sales support provide the foundation for further expansion. The company is also exploring the use of Compass Software’s online stair configurator to further streamline its processes and enhance its ability to handle complex projects efficiently.

“Compass Software is one of our most valued partners,” Juhan concludes. “Its flexibility, reliability, and strong support network make it an essential part of our business.” With its commitment to innovation, efficiency, and strong partnerships, Aru Grupp is poised to continue its impressive growth in the stair manufacturing industry.

Aru Grupp’s journey demonstrates how the right software can revolutionize manufacturing, enabling smarter, more efficient, and globally connected production. For stair manufacturers looking to scale their business, Compass Software offers a proven solution that drives success.